In the intricate web of global commerce, where goods traverse continents and cross countless borders, supply chain professionals have become increasingly sophisticated in their approach to optimization. Modern supply chains employ predictive analytics to forecast demand, leverage artificial intelligence to optimize routing, and utilize Internet of Things sensors to track shipments in real-time. Yet despite these technological advances, a fundamental weakness persists at the very foundation of supply chain operations one that often goes unrecognized until it brings entire logistics networks to a grinding halt.

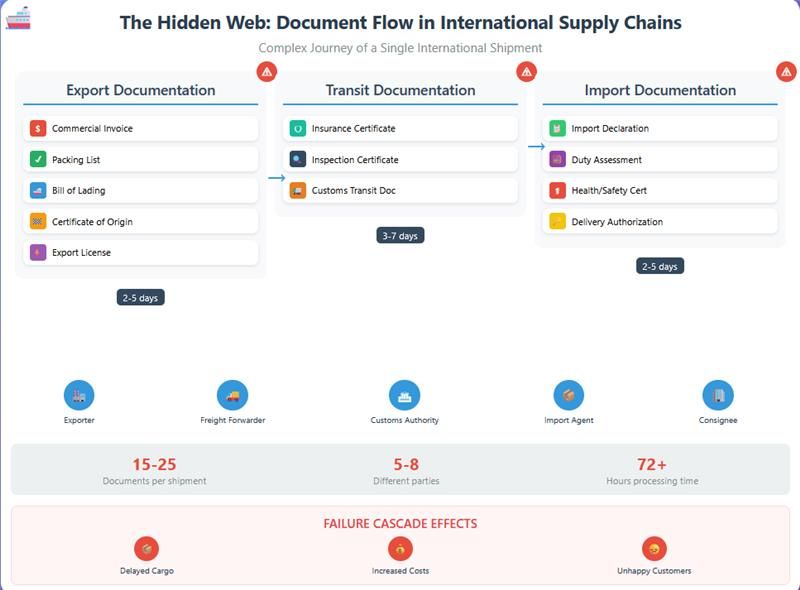

The weakness lies not in the sophisticated algorithms or the connected devices, but in something far more mundane yet critically important: the processing of documents. Every shipment that moves through the global supply chain generates a paper trail of extraordinary complexity. Bills of lading must be verified and processed. Customs declarations require meticulous review and approval. Certificates of origin need validation. Commercial invoices demand reconciliation against purchase orders. Inspection certificates must be authenticated. Each of these documents represents a potential chokepoint where delays can cascade into supply chain disruptions that ripple across entire industries.

The relationship between document processing failures and supply chain disruptions represents one of the most underexplored yet consequential aspects of modern logistics management. While supply chain executives invest millions in sophisticated forecasting systems and real-time tracking technologies, many continue to rely on manual, error-prone document processing workflows that were designed for a simpler era of commerce. This disconnect between advanced supply chain technology and antiquated document processing creates hidden bottlenecks that undermine the effectiveness of even the most sophisticated logistics operations.

Understanding this relationship requires us to examine how documents function as the nervous system of supply chain operations. Every physical movement of goods must be accompanied by corresponding documentation that provides legal authorization, customs clearance, quality assurance, and chain of custody verification. When document processing fails or becomes delayed, the physical movement of goods cannot proceed, regardless of how efficiently the rest of the supply chain operates. A container ship might arrive at port precisely on schedule, but if the customs documentation contains errors or cannot be processed quickly enough, the cargo remains inaccessible, creating delays that compound throughout the supply chain.

The complexity of international trade documentation has grown exponentially as global commerce has become more sophisticated. A single shipment crossing international borders might require dozens of different documents, each with specific formatting requirements, regulatory compliance standards, and approval workflows. These documents must often be processed by multiple parties across different time zones, languages, and regulatory frameworks. The potential for errors, delays, and miscommunications multiplies with each additional document and each additional party involved in the process.

To understand how document processing failures create supply chain disruptions, we must first examine the specific ways in which documents function within logistics operations. Unlike many other business processes where document errors might result in administrative inconvenience, supply chain documentation errors can immediately halt the physical movement of goods worth millions of dollars.

Consider the bill of lading, often called the most important document in international trade. This document serves simultaneously as a receipt for goods shipped, a contract between the shipper and carrier, and a document of title that can be used to claim ownership of the goods. When a bill of lading contains errors incorrect product descriptions, wrong quantities, mismatched container numbers, or improper endorsements it can prevent the release of cargo at destination ports. The goods sit in expensive storage facilities while documentation issues are resolved, accruing demurrage charges and creating delays that affect every downstream customer and supplier relationship.

The customs declaration process presents another critical vulnerability point where document processing failures translate directly into supply chain disruptions. Customs authorities around the world have become increasingly sophisticated in their use of automated systems to screen incoming shipments for compliance with trade regulations, security requirements, and duty assessments. However, these automated systems are highly sensitive to data quality issues. A simple error in product classification codes, country of origin declarations, or value assessments can trigger automated holds that prevent cargo clearance for days or weeks while manual reviews are conducted.

The cascading effects of document processing delays become particularly severe in just-in-time manufacturing environments where suppliers deliver components precisely when needed to minimize inventory carrying costs. When a critical component shipment is delayed due to customs documentation issues, manufacturing lines can be forced to shut down while alternative supplies are sourced. The cost of these production disruptions often exceeds the value of the original delayed shipment by orders of magnitude.

Quality certificates and inspection documents represent another category of documentation where processing failures can create significant supply chain disruptions. Many industries require specific certifications to verify that imported goods meet safety, quality, or regulatory standards. Pharmaceutical companies must provide certificates of analysis for active ingredients. Food importers need health certificates and inspection reports. Electronics manufacturers require compliance certificates for electromagnetic compatibility and safety standards. When these certificates are delayed, contain errors, or cannot be properly authenticated, entire shipments can be rejected or held pending additional testing and verification.

The complexity of managing these documentation requirements has grown significantly as supply chains have become more global and specialized. A manufacturer sourcing components from multiple countries must navigate different documentation requirements for each supplier relationship while ensuring that all documents are properly coordinated to support just-in-time delivery schedules. The administrative burden of managing these document flows often requires dedicated staff members whose primary responsibility is chasing down missing documents, correcting errors, and coordinating approvals across multiple time zones and languages.

The Economic Impact of Document Processing Inefficiencies

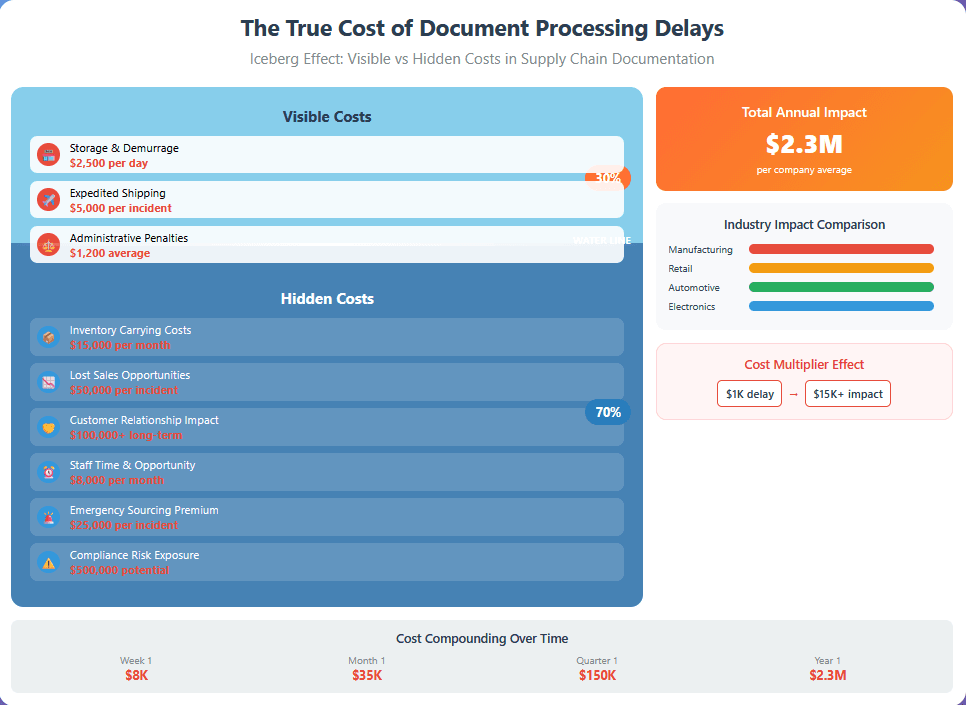

The financial implications of document processing failures extend far beyond the immediate costs of delayed shipments or storage fees. When documents cannot be processed efficiently, the resulting supply chain disruptions create a cascade of economic impacts that affect multiple stakeholders across extended supply networks.

Transportation costs represent one of the most immediate areas where document processing inefficiencies create economic impact. When shipments are delayed due to documentation issues, transportation resources that were scheduled for specific delivery windows become unavailable for other cargo. Ships miss their departure schedules, requiring expensive repositioning to maintain service commitments. Trucks arrive at destinations to find that cargo cannot be released due to missing or incorrect documentation, resulting in empty return trips and inefficient asset utilization. Air cargo, which operates on particularly tight schedules due to the high cost of aircraft operations, can be especially vulnerable to document-driven delays that prevent cargo from making scheduled connections.

Inventory carrying costs multiply rapidly when document processing delays prevent goods from reaching their intended destinations on schedule. Companies that have carefully optimized their inventory levels to minimize carrying costs suddenly find themselves maintaining emergency stock levels to compensate for unpredictable documentation delays. The additional inventory investment ties up working capital and increases storage costs while reducing overall supply chain efficiency. For companies operating in industries with rapid product obsolescence, such as electronics or fashion, documentation delays can result in products becoming unsaleable due to market timing issues.

Customer relationship costs represent another significant category of economic impact from document processing failures. When retailers cannot receive merchandise on schedule due to customs documentation delays, they may lose sales during critical selling periods or be forced to source alternative products at higher costs. Business-to-business customers who depend on predictable delivery schedules for their own operations may be forced to find alternative suppliers when documentation issues create chronic reliability problems. The long-term value of customer relationships often far exceeds the immediate revenue impact of any single delayed shipment.

Compliance costs increase substantially when document processing systems cannot keep pace with evolving regulatory requirements. International trade regulations change frequently as governments update security procedures, modify duty structures, or implement new environmental standards. Companies that rely on manual document processing systems often struggle to implement these regulatory changes consistently across all their trade lanes, resulting in compliance violations that can trigger expensive audits, penalties, or even suspension of import privileges.

The opportunity costs of inefficient document processing may represent the largest category of economic impact, though they are often the most difficult to quantify. When supply chain professionals must dedicate significant time and attention to resolving documentation issues, they have less capacity to focus on strategic initiatives that could improve overall supply chain performance. The human resources devoted to manual document processing, error correction, and exception management represent a significant investment that could potentially be redirected toward higher-value activities if document processing could be automated and streamlined.

Traditional Approaches and Their Limitations

The evolution of document processing in supply chain operations has followed a predictable pattern that mirrors the broader digitization of business processes. Initially, most companies relied entirely on paper-based systems where physical documents were manually processed, reviewed, and filed. As basic computing systems became available, many organizations implemented simple digitization approaches that converted paper documents into electronic formats but maintained essentially the same manual review and approval processes.

Electronic Data Interchange systems represented the first major attempt to standardize and automate supply chain document processing. EDI systems allowed trading partners to exchange structured business documents such as purchase orders, invoices, and shipping notices using standardized message formats. While EDI provided significant improvements in processing speed and accuracy compared to paper-based systems, it required substantial upfront investment in system integration and ongoing maintenance costs that limited adoption primarily to large enterprises with high transaction volumes.

The limitations of traditional EDI systems became apparent as supply chains became more complex and global. EDI standards were designed for relatively simple trading relationships between established partners who could invest the time and resources necessary to implement and maintain complex integration projects. However, modern supply chains often involve temporary or occasional trading relationships with suppliers who cannot justify the cost of EDI implementation for limited transaction volumes. Additionally, EDI systems typically handle only structured data formats and cannot easily accommodate the wide variety of document types and formats that are common in international trade.

Workflow management systems represented another approach that many organizations implemented to improve document processing efficiency. These systems allowed companies to define approval workflows that automatically route documents to appropriate reviewers based on predefined business rules. While workflow systems provided better visibility and control over document processing status, they still relied fundamentally on manual review processes and could not address the underlying data quality issues that create most document processing delays.

The emergence of cloud-based document management platforms offered improved accessibility and collaboration capabilities, allowing distributed teams to access and process documents from multiple locations. However, these platforms typically focused on document storage and sharing rather than automated processing capabilities. Users could access documents more easily, but the actual work of reviewing, validating, and approving documents remained a manual process that was subject to human error and processing delays.

Optical Character Recognition technology began to address some of the data entry challenges associated with document processing by automatically converting scanned documents into editable text formats. Early OCR systems, however, were notoriously unreliable when processing the complex, multi-format documents common in supply chain operations. Bills of lading, customs forms, and inspection certificates often contain both printed and handwritten text in multiple languages and formats that challenged the capabilities of traditional OCR systems. The error rates associated with OCR processing often created more problems than they solved, as users had to carefully review and correct automatically extracted data before it could be trusted for critical supply chain decisions.

Template-based document processing systems attempted to improve OCR accuracy by creating predefined templates for common document types. These systems could more reliably extract data from documents that matched predefined templates, but they struggled with the variation in document formats that is common in international trade. Different shipping lines use different bill of lading formats, various countries have unique customs forms, and suppliers often use proprietary formats for certificates and inspection reports. The maintenance burden of creating and updating templates for every possible document format often exceeded the benefits of automated processing.

Integration challenges represented another significant limitation of traditional document processing approaches. Most companies use multiple software systems for different aspects of supply chain management, including Enterprise Resource Planning systems, Transportation Management Systems, Warehouse Management Systems, and Customs Management Systems. Traditional document processing solutions were typically standalone systems that could not easily share data with these other critical systems, creating information silos that reduced overall supply chain visibility and required manual data re-entry across multiple platforms.

The Modern Document AI Revolution

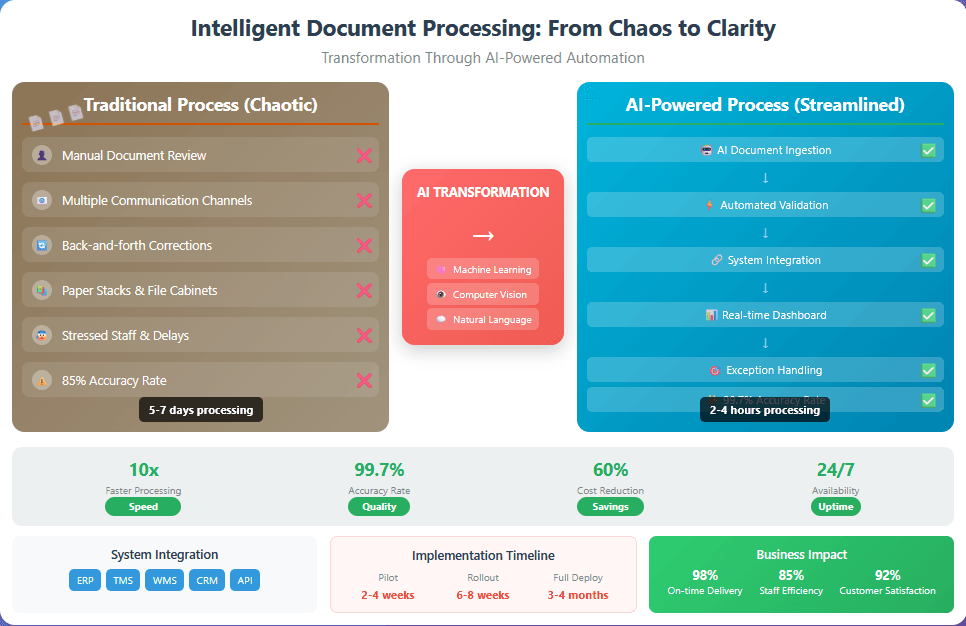

The emergence of artificial intelligence technologies specifically designed for document processing has begun to address many of the fundamental limitations that have plagued traditional approaches to supply chain documentation. Modern document AI systems leverage machine learning algorithms that can understand document content and context in ways that were impossible with earlier technologies, creating opportunities for unprecedented levels of automation and accuracy in document processing workflows.

Natural Language Processing capabilities allow modern document AI systems to understand the meaning and context of document content rather than simply extracting text characters. This contextual understanding enables the systems to identify and correct common errors, validate data consistency across related documents, and even detect potential fraud or compliance issues that might not be apparent to human reviewers. For example, a document AI system processing a commercial invoice can automatically verify that the product descriptions match the corresponding bill of lading, that unit prices are consistent with historical patterns, and that country of origin declarations align with shipping routes.

Computer vision technologies have evolved far beyond traditional OCR to provide sophisticated image analysis capabilities that can process complex document layouts, handwritten text, and even damaged or partially obscured documents. Modern document AI systems can automatically identify document types, extract relevant data fields regardless of document format variations, and maintain high accuracy levels even when processing documents that contain multiple languages, currencies, or measurement units. This flexibility allows organizations to process documents from suppliers and partners around the world without requiring template customization or format standardization.

Machine learning algorithms enable document AI systems to continuously improve their processing accuracy by learning from both successful processing examples and error corrections provided by human reviewers. This adaptive capability means that document AI systems become more accurate and efficient over time, particularly when processing documents from frequently used suppliers or trading partners. The systems can learn to recognize supplier-specific document formats, understand industry-specific terminology, and adapt to regulatory changes that affect document requirements.

Intelligent data validation represents one of the most valuable capabilities of modern document AI systems. Rather than simply extracting data from documents, these systems can validate the extracted data against multiple sources including historical patterns, regulatory requirements, and related documents within the same shipment. For example, when processing a customs declaration, the system can automatically verify that declared values are consistent with commercial invoices, that product classifications match regulatory databases, and that duty calculations are accurate according to current tariff schedules.

Real-time processing capabilities allow document AI systems to process documents immediately upon receipt, rather than requiring batch processing or manual intervention. This real-time capability is particularly important for time-sensitive supply chain operations where delays in document processing can have immediate impacts on cargo clearance or delivery schedules. Documents can be processed automatically as they are received via email, uploaded to web portals, or transmitted through EDI systems, providing instant feedback on any issues that require attention.

Integration capabilities represent a fundamental advantage of modern document AI platforms compared to traditional standalone solutions. These systems are designed from the ground up to integrate seamlessly with existing supply chain management systems, automatically updating relevant databases and triggering appropriate workflow actions based on processed document content. When a bill of lading is processed, the system can automatically update shipment tracking systems, notify relevant stakeholders of cargo status changes, and trigger customs clearance processes without requiring manual intervention.

Exception handling capabilities allow document AI systems to identify documents or data elements that require human review while automatically processing routine documents that meet predefined quality and compliance standards. This hybrid approach maximizes processing efficiency while maintaining appropriate oversight for complex or unusual situations. The systems can be configured to route exceptions based on various criteria including document type, supplier relationship, country of origin, cargo value, or specific compliance requirements.

Industry-Specific Applications and Benefits

The application of intelligent document processing in supply chain operations varies significantly across different industries, each of which faces unique documentation challenges and regulatory requirements. Understanding these industry-specific applications helps illustrate the broad potential for document AI to address supply chain bottlenecks across diverse sectors of the global economy.

The pharmaceutical industry presents one of the most complex documentation environments in international trade, where product safety and regulatory compliance requirements create extensive documentation workflows that are critical to maintaining supply chain continuity. Pharmaceutical companies must manage certificates of analysis for active pharmaceutical ingredients, good manufacturing practice certificates for production facilities, import licenses for controlled substances, temperature monitoring records for cold chain shipments, and regulatory approvals for new product introductions. Each category of documentation has specific formatting requirements, approval workflows, and retention periods that must be managed consistently across multiple regulatory jurisdictions.

Document AI systems designed for pharmaceutical supply chains can automatically validate certificates of analysis against product specifications, verify that temperature monitoring data falls within acceptable ranges, and ensure that import licenses are valid for specific product categories and quantities. The systems can also track expiration dates for various certificates and approvals, automatically triggering renewal processes before documents expire and potentially disrupt supply chain operations. For pharmaceutical companies operating in multiple countries, document AI can manage the complexity of different regulatory requirements while maintaining consistent data quality standards across all markets.

The automotive industry faces unique documentation challenges related to the complex supply chains that support just-in-time manufacturing operations. Automotive manufacturers typically source components from hundreds or thousands of suppliers located around the world, each of which must provide specific documentation to support quality control, regulatory compliance, and supply chain traceability requirements. Material certificates verify that raw materials meet specific strength and composition requirements. Quality inspection reports document compliance with manufacturing tolerances. Origin certificates support trade agreement benefits and regulatory compliance requirements.

Document AI applications in automotive supply chains focus particularly on maintaining the data consistency and timing precision that are essential for just-in-time operations. The systems can automatically cross-reference material certificates with purchase order specifications, verify that quality inspection data falls within acceptable tolerances, and ensure that all required documentation is available before components are released for production use. When documentation issues are identified, the systems can immediately alert relevant stakeholders and suggest alternative suppliers or expedited processing options to minimize production disruptions.

The electronics industry must navigate particularly complex documentation requirements related to regulatory compliance, intellectual property protection, and rapid product lifecycle management. Electronics manufacturers must manage compliance certificates for electromagnetic compatibility, safety approvals for consumer products, export control documentation for dual-use technologies, and supply chain security certifications for government contracts. The rapid pace of product development in the electronics industry means that documentation requirements change frequently as new products are introduced and existing products are modified or discontinued.

Document AI systems supporting electronics supply chains emphasize flexibility and adaptability to accommodate rapidly changing product specifications and regulatory requirements. The systems can automatically identify when new compliance certificates are required based on product modifications, track the status of regulatory approvals across multiple jurisdictions, and maintain detailed audit trails that support intellectual property protection and export control compliance. For electronics companies with complex global supply chains, document AI can provide real-time visibility into documentation status across all supplier relationships and product categories.

The food and beverage industry faces unique documentation challenges related to product safety, quality control, and traceability requirements that are essential for consumer protection and regulatory compliance. Food importers must manage health certificates from exporting countries, laboratory analysis reports for contamination testing, organic certification documents, and traceability records that can support rapid response to food safety incidents. The perishable nature of many food products means that documentation delays can result in product spoilage and total loss of shipment value.

Document AI applications in food and beverage supply chains prioritize processing speed and accuracy to minimize delays that could affect product quality or safety. The systems can automatically verify that health certificates are current and properly endorsed, validate that laboratory results meet import requirements, and ensure that organic certification documentation supports product labeling claims. For companies managing multiple product categories with different regulatory requirements, document AI can automatically apply appropriate validation rules based on product type, country of origin, and destination market requirements.

The chemical industry must manage extensive documentation related to product safety, environmental compliance, and transportation regulations that govern the movement of hazardous materials. Chemical companies must process safety data sheets that provide detailed information about product hazards and handling requirements, environmental certificates that document compliance with pollution control regulations, and transportation documents that ensure compliance with dangerous goods regulations. The complexity of chemical product classifications and the severity of potential safety and environmental consequences make accurate documentation processing particularly critical for this industry.

Document AI systems designed for chemical supply chains incorporate extensive validation capabilities that can verify product classifications against multiple regulatory databases, ensure that safety data sheets contain all required information elements, and validate that transportation documentation complies with applicable dangerous goods regulations. The systems can also track regulatory changes that affect product classifications or transportation requirements, automatically updating relevant documentation and alerting stakeholders when changes require action.

Implementation Strategies and Best Practices

Successful implementation of intelligent document processing in supply chain operations requires careful planning and attention to the specific organizational, technical, and operational factors that influence adoption success. The complexity of supply chain documentation workflows and the critical nature of supply chain operations make it essential to approach implementation with a comprehensive strategy that addresses both technical capabilities and change management requirements.

Pilot program development represents the most effective approach for organizations beginning their document AI implementation journey. Rather than attempting to automate all document processing workflows simultaneously, successful implementations typically begin with a carefully selected pilot program that focuses on a specific document type, trading partner relationship, or geographic region. This focused approach allows organizations to develop experience with the technology, refine processing workflows, and demonstrate value before expanding to broader applications.

The selection of pilot program scope requires careful consideration of several factors including document volume, processing complexity, and business impact. High-volume, routine document types such as commercial invoices or packing lists often provide good pilot opportunities because they offer substantial automation potential while presenting relatively straightforward processing challenges. However, organizations may also choose to focus pilot programs on high-impact, complex document types such as customs declarations or quality certificates where processing improvements can provide immediate and visible business benefits.

Data quality assessment represents a critical foundation for successful document AI implementation. Most organizations discover that their existing document processing workflows have tolerated data quality issues that must be addressed before automated processing can be effective. Inconsistent document formats, incomplete data fields, and poor image quality can significantly impact the accuracy of automated processing systems. A comprehensive data quality assessment should evaluate both the technical characteristics of existing documents and the business processes that generate and manage those documents.

Training data development requires careful attention to ensure that document AI systems can achieve acceptable accuracy levels for the specific document types and formats used by each organization. While many document AI platforms include pre-trained models for common document types, supply chain documents often contain industry-specific terminology, unique format variations, and specialized data fields that require customized training approaches. Organizations should plan to invest significant effort in collecting representative training documents, annotating data fields accurately, and validating training results before deploying automated processing capabilities.

Integration planning must address the complex technical environment that characterizes most supply chain operations. Document AI systems must integrate with multiple existing systems including Enterprise Resource Planning platforms, Transportation Management Systems, Customs Management Systems, and various supplier portals and communication systems. The integration architecture should support real-time data exchange, maintain data consistency across multiple systems, and provide appropriate error handling and exception management capabilities.

Change management considerations are particularly important for document processing implementations because they often affect multiple stakeholder groups both within the organization and among external trading partners. Internal stakeholders may include procurement teams, logistics coordinators, customs brokers, quality assurance personnel, and finance teams, each of which may have different requirements and concerns about automated processing capabilities. External stakeholders such as suppliers, freight forwarders, and customs authorities may also be affected by changes to document processing workflows.

Performance measurement frameworks should be established before implementation begins to provide objective criteria for evaluating success and identifying areas for improvement. Key performance indicators might include processing accuracy rates, processing time reductions, exception handling efficiency, and cost savings achieved through automation. Organizations should also establish baseline measurements for current performance levels to enable accurate assessment of improvement gains.

Security and compliance considerations require particular attention when implementing document AI systems because supply chain documents often contain sensitive business information and must comply with various regulatory requirements. Document AI platforms should provide appropriate access controls, audit logging capabilities, and data encryption to protect confidential information. Compliance requirements may include data residency restrictions, audit trail maintenance, and specific approval workflows that must be maintained even when processing is automated.

Continuous improvement processes should be established to ensure that document AI systems continue to provide value as business requirements evolve and processing volumes grow. Machine learning algorithms can continue to improve accuracy over time, but they require ongoing monitoring and adjustment to maintain optimal performance. Organizations should plan to regularly review processing accuracy, update training data sets, and refine business rules to accommodate changes in document formats, regulatory requirements, or business processes.

Vendor selection criteria should evaluate not only current technical capabilities but also the vendor's ability to support long-term implementation success. Important considerations include the vendor's experience with supply chain applications, integration capabilities with existing systems, training and support resources, and roadmap for future capability development. Organizations should also evaluate the vendor's financial stability and customer references to ensure that they can provide reliable support for mission-critical supply chain operations.

Measuring Success and Return on Investment

The measurement of success for intelligent document processing implementations in supply chain operations requires a comprehensive approach that captures both quantitative benefits and qualitative improvements that may be difficult to measure directly. The complexity of supply chain operations and the interconnected nature of document processing workflows mean that benefits often appear in unexpected areas and may not be immediately apparent through traditional measurement approaches.

Direct cost savings represent the most straightforward category of benefits to measure and typically include reductions in labor costs associated with manual document processing, decreases in storage and printing costs for paper-based systems, and elimination of expedited shipping costs that were previously required to deliver physical documents. Organizations implementing document AI systems often find that these direct cost savings exceed their initial expectations because they had not fully recognized the hidden costs associated with manual processing workflows, including the time spent by various staff members in tracking down missing documents, correcting errors, and managing exceptions.

Processing efficiency improvements can be measured through metrics such as document processing time reductions, error rate decreases, and exception handling efficiency gains. However, these measurements must account for the fact that document AI systems may initially require more time per document as users learn new workflows and systems are fine-tuned for optimal performance. Organizations should establish baseline measurements before implementation and track improvements over several months to capture the full benefits of system optimization and user learning curves.

Supply chain performance improvements represent some of the most significant benefits of document AI implementation, but they can be challenging to measure because they depend on many factors beyond document processing efficiency. Metrics such as on-time delivery performance, inventory turnover rates, and customer satisfaction scores may show improvement following document AI implementation, but isolating the contribution of improved document processing requires careful analysis of other variables that might influence these performance indicators.

Compliance and risk reduction benefits often provide substantial value but may be difficult to quantify until problems that would have occurred without document AI systems are avoided. Organizations can measure improvements in compliance audit results, reductions in customs delays, and decreases in regulatory penalties or fines. However, the most significant benefits may be the avoidance of major compliance incidents or supply chain disruptions that could have resulted in much larger costs and business impacts.

Customer and supplier relationship improvements represent another category of benefits that can be challenging to quantify but may provide substantial long-term value. Document AI systems can improve the reliability and predictability of supply chain operations, leading to stronger relationships with customers and suppliers who value consistent performance. Organizations can measure these benefits through customer satisfaction surveys, supplier scorecards, and retention rates, though the impact of document processing improvements may be difficult to separate from other relationship factors.

Working capital optimization represents a significant financial benefit that results from improved supply chain efficiency and predictability. When documents are processed more quickly and accurately, goods move through supply chains more efficiently, reducing inventory carrying costs and improving cash flow cycles. Organizations can measure these benefits through inventory turnover rates, days sales outstanding, and cash conversion cycle improvements, though these metrics are influenced by many factors beyond document processing efficiency.

Competitive advantage benefits may represent the most valuable long-term impact of document AI implementation, but they are also the most difficult to measure directly. Organizations that can process documents more efficiently than their competitors may be able to offer faster delivery times, lower costs, or higher service levels that provide market differentiation. These benefits might be measured through market share gains, pricing premium capabilities, or customer acquisition rates, though attributing these improvements specifically to document processing capabilities requires careful analysis.

Return on investment calculations for document AI implementations should account for both the direct costs of system implementation and ongoing operational costs, as well as the full range of benefits that result from improved document processing capabilities. Implementation costs typically include software licensing fees, integration development costs, training expenses, and the time invested by internal staff in system deployment and optimization. Ongoing costs include system maintenance, user support, and continuous improvement activities.

The time horizon for ROI calculations should reflect the fact that many benefits of document AI implementation increase over time as systems are optimized, users become more proficient, and business processes are refined to take advantage of automated capabilities. Organizations often find that initial ROI calculations underestimate the long-term benefits because they do not fully account for the compound effects of improved efficiency, enhanced capabilities, and reduced risk that accumulate over time.

Future Trends and Strategic Implications

The trajectory of intelligent document processing technology suggests that current capabilities represent only the beginning of a transformation that will fundamentally reshape how supply chain operations manage information flows and make decisions. Understanding these emerging trends and their strategic implications is essential for supply chain leaders who want to position their organizations to take advantage of evolving capabilities while avoiding the risks associated with technological obsolescence.

Artificial intelligence capabilities continue to evolve rapidly, with new developments in machine learning algorithms, natural language processing, and computer vision providing increasingly sophisticated document processing capabilities. Advanced neural network architectures are enabling document AI systems to understand document content at levels that approach human comprehension, including the ability to interpret context, detect inconsistencies, and make inferences based on incomplete information. These advancing capabilities will enable document AI systems to handle increasingly complex document types and processing scenarios that currently require human expertise.

Integration with blockchain technology represents an emerging trend that could provide new levels of security, transparency, and trust in supply chain documentation. Blockchain-based document management systems can create immutable records of document creation, modification, and approval that provide enhanced audit trails and fraud prevention capabilities. For supply chain operations that span multiple organizations and jurisdictions, blockchain integration could enable new levels of collaboration and trust that reduce the need for redundant verification processes and enable more efficient cross-border trade.

Real-time analytics and predictive capabilities are emerging as document AI systems become more sophisticated in their ability to analyze patterns and trends in document content and processing workflows. These capabilities will enable supply chain organizations to identify potential problems before they create disruptions, optimize document processing workflows based on predictive insights, and make more informed decisions about supplier relationships and trade lane management. Predictive analytics could also enable dynamic optimization of supply chain operations based on real-time analysis of document content and external factors such as weather, political developments, or market conditions.

Internet of Things integration represents another frontier where document processing capabilities will intersect with physical supply chain operations. As sensors and connected devices become more prevalent in supply chain operations, document AI systems will be able to automatically correlate physical events with documentary evidence, creating new levels of supply chain visibility and control. For example, temperature sensors in pharmaceutical cold chain shipments could automatically generate compliance documentation, while GPS tracking systems could automatically update customs declarations with accurate routing information.

Regulatory technology applications are emerging as governments and regulatory agencies adopt new approaches to trade facilitation and compliance monitoring. Document AI systems will increasingly interface directly with government systems to provide real-time compliance monitoring, automated regulatory filing, and streamlined approval processes. These capabilities could significantly reduce the administrative burden associated with international trade while providing governments with enhanced visibility into cross-border commerce for security and revenue purposes.

Cross-industry standardization efforts are beginning to emerge as organizations recognize the benefits of common approaches to document processing and data exchange. Industry consortiums and standards organizations are developing new frameworks for document formats, data elements, and processing workflows that could reduce the complexity of multi-party supply chain operations. Document AI systems that support these emerging standards will provide organizations with greater flexibility in supplier relationships and reduced implementation costs for new trading partnerships.

Autonomous supply chain operations represent the ultimate evolution of intelligent document processing, where document AI systems will operate with minimal human intervention to manage routine supply chain operations. These systems will automatically process documents, make routine decisions, handle exceptions within predefined parameters, and escalate complex issues to human oversight only when necessary. The development of autonomous capabilities will require continued advances in artificial intelligence, but the potential benefits include dramatic improvements in processing speed, consistency, and cost-effectiveness.

Strategic implications of these technological trends extend beyond operational efficiency improvements to encompass fundamental changes in competitive advantage and business model opportunities. Organizations that successfully implement advanced document processing capabilities may be able to offer new services to customers and suppliers, enter new markets that were previously inaccessible due to documentation complexity, and achieve cost structures that provide sustainable competitive advantages.

The geographic implications of advanced document processing capabilities could reshape global trade patterns as organizations gain the ability to manage complex documentation requirements that previously limited their supplier and market choices. Small and medium-sized enterprises may gain access to international trade opportunities that were previously available only to large organizations with extensive administrative capabilities, while established traders may be able to expand into new markets and product categories that require specialized documentation expertise.

Investment strategies for document AI implementation should consider both current capabilities and future technology roadmaps to ensure that technology investments provide long-term value rather than becoming obsolete as capabilities evolve. Organizations should evaluate vendors based on their research and development capabilities, partnership relationships with technology providers, and commitment to supporting evolving standards and integration requirements.

Risk management considerations must account for both the risks of implementing new technologies and the risks of failing to adopt capabilities that become essential for competitive performance. Organizations that delay document AI implementation may find themselves at increasing competitive disadvantages as early adopters achieve efficiency gains and cost reductions that enable superior market performance. However, organizations must also manage the risks associated with technology implementation, including system integration challenges, user adoption issues, and vendor dependency considerations.

The transformation of supply chain operations through intelligent document processing represents both an opportunity and an imperative for organizations competing in global markets. The hidden bottlenecks created by inefficient document processing have constrained supply chain performance for too long, creating vulnerabilities that undermine even the most sophisticated logistics operations. As document AI technologies mature and become more accessible, organizations that successfully implement these capabilities will achieve sustainable competitive advantages that extend far beyond operational efficiency improvements to encompass new business model opportunities and market expansion possibilities.

The journey toward intelligent document processing requires careful planning, substantial investment, and sustained commitment to organizational change. However, the potential benefits improved efficiency, reduced costs, enhanced compliance, and stronger competitive position justify the effort required for successful implementation. Supply chain leaders who recognize the strategic importance of document processing and take action to implement intelligent solutions will position their organizations for success in an increasingly complex and competitive global marketplace.